Greetings chaps,

Here's a bit of dialogue between Mike Wood and myself, following his second flight in the Z-21A fitted with wheelbrakes and a tailwheel. I thought that this might be of general interest to Flitzer builders and potential builders.

Best wishes,

Lynn WilliamsSubject: Update

Hi Mike

Hi Lynn, thanks for keeping me in the loop - I have very little time to do everything I'd like to at the moment, and keeping in touch (or even making initial contacts, in some cases) is difficult. Just to keep you updated, G-FLIZ has flown for the second - or rather, third time, if we count your short trip of some years back. handling on concrete is a real pleasure with a steerable tailwheel, and the brakes work just as I'd hoped. They're really a necessity on a firm surface as the aircraft accelerates very quickly when taxying with a tailwind, even with the throttle closed - just gets blown along.

Lynn: Absolutely. On grass, skid equipped, there is always enough drag to control the situation, using aileron to steer downwind,

Mike: There is no appreciable heating of the discs even with prolonged application - I persuaded a brave friend to do the "wet finger test" to confirm - no hissing of boiling spit! The tailwheel has now been changed for one of the same (100mm) diameter but with aluminium wheel, rubber tyre and proper bearings. I didn't want to do this until the original setup had been proven, but in fact the original hard rubber item would probably have been good for a long time, just a bit noisy and transmitted a harsh vibration.

Lynn: Exactly like the shopping trolley wheel we had on the Taylor Monoplane prototype back in '73. Being enclosed the noise was even worse, like being trapped in a cello while it was dragged downstairs.

Mike: The levers on the stick work fine and enable diff braking if necessary, but a more elegant solution would be to incorporate a "mixing block" on the cockpit floor that would enable the use of levers set alongside the pedals as well as a full lock lever on the stick, similar to the Nipper (I believe). This is what I made for the Taylor. This would entail doing without the baggage locker, though, so I may run with the present arrangement for a while, we'll see.

Regarding the flying, reworking the air scoops to take a much closer profile around the back of the aft heads fins has worked wonders with the CHT. Full power (2750 RPM as indicated) gives an initial climb rate of 500fpm, but I'm holding the nose down (and the speed up) until I feel more comfortable with the stall characteristics, which I've not had time to explore fully. Max level IAS is 73 kts IAS at 2850. The CHT doesn't rise above 400 throughout, and oil Ts&Ps are well down and up respectively, so the ducting is about right there - perhaps a bit on the cool side - we'll see. The only reason I've not flown more is an annoying oil leak - not a showstopper, but messy - but I think I've traced that. Again, the weekend will prove it. Thought is that rpm and hence roc/ias will improve as things get "bedded in". What's your opinion?

Lynn: Well it certainly should. With the 'unrefined' propeller on 'VAW as described, the motor rpm is currently held down to 3000 in the air, which relates to about 90 mph. At 2850 it achieves 87 mph (ie. at what I consider max cruise) or 75.5 Kts. Your 73 kts. at 2850 seems about in line with this, at 84 mph, but obviously it depends very much on the instrument calibration and the ambient T&P on the day. Climb is about 700-750 fpm. at full power indicating 60 mph, for optimum cooling.

Stalling is its most docile characteristic, showing good manners with a straight ahead nod, power off, and falling off on a wing (to port) at full power, ie. identical to the prototype when fitted with the bigger tailplane. Both events are attended by trembles through the airframe, with short-period wing rock, followed by hunting in pitch, the magnitude of which being proportional to the attitude achieved and the power selected, with rudder controlling the incipient wing drop, There is no mistaking the condition. Recovery is instantaneous on release of back pressure.

Mike: Landing is always something to be contemplated quietly before committing yourself, I think, but FLIZ handles beautifully right down to the flare. I've had 30-off crosswind up to 10 kts up to now with no problems, although she does seem to wobble a bit as she settles, reminding me of comments I've read about "narrow track" gear on WW2 fighters. I know that you maintain that the gear isn't narrow at all, but it gives a pleasant lively feel to the aircraft, anyway!

Lynn: I've encountered crosswinds of 25 kts. at least 20 degrees off on grass, and the aeroplane has coped superbly, having plenty of aileron power, and the rudder is also more than adequate - although it tried to weathercock smartly each time the attitude changed, when raising the tail on T/O, or lowering the tail from a wheel-landing attitude. Obviously those wind conditions would be much more difficult, if not impossible on tarmac.

The track equates to about 25% of wing span, and the wings are light and the bungees should be stiff, so any lateral waddle should be controllable through bungee tension. I've dragged a wing in the grass when attempting a very tight turn in a stiff wind, but that was pushing the envelope somewhat.

Mike: So, that's it for now. pictures to come when I've got time. Will release the drawings and notes on the brakes and tailwheel once all testing is complete, but in the meantime would suggest prospective "blacktop" operators get friendly with their local supermarket - the starting point's a shopping trolley.

See you at Kemble - bring your earplugs.

Regards,

Mike Wood

Lynn: I look forward to seeing you there, and getting a close look at a Tornado. I look forward eagerly to seeing the pictures of the new G-FLIZ.

Best wishes,

Lynn

Ian Wasey has machined the first elements of what will probably be the standard, PFA-approved brake system for the Z-series. He is prepared to provide drawings of these to the members of the FSV in due course.

BML3V.pdf - 3-View Drawings |

|

|

|

|

|

|

|

August 7, 2006

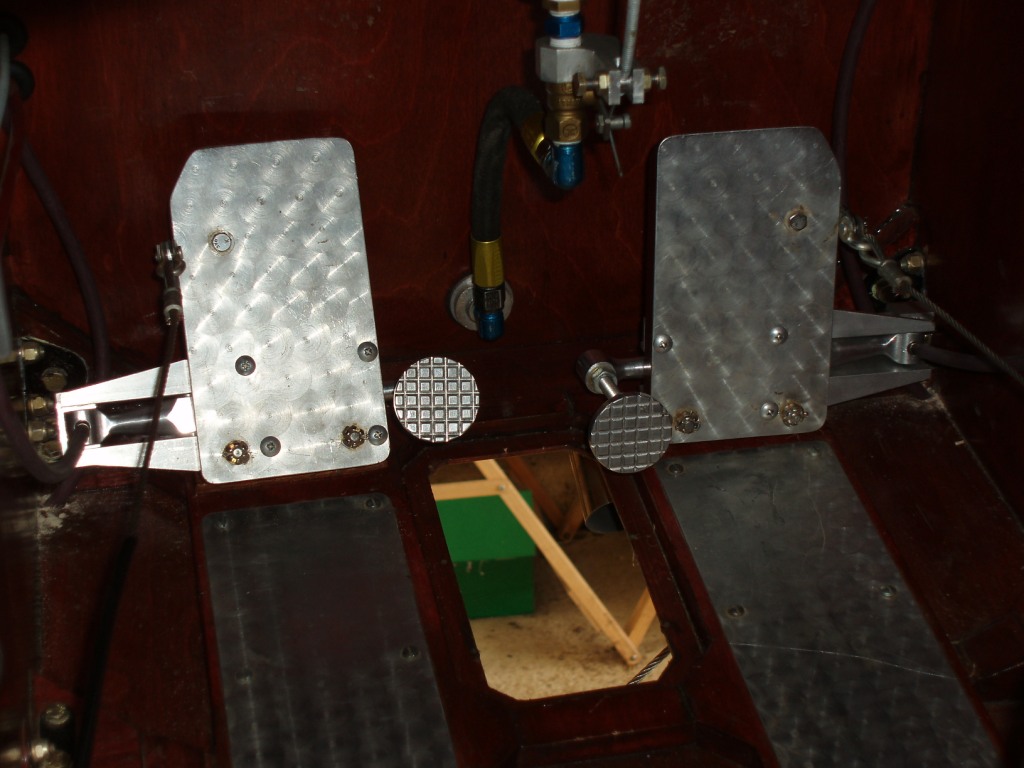

The brake system designed and manufactured by my Father, Ian are now fitted and have undergone taxi trials, with very pleasing results, enabling excellent manoeuvrability at low taxi speeds. The brakes are easy to operate with ones heel, enabling simultaneous rudder and brake operation, yet one has to make a distinct foot movement to position ones heels onto the brake pedals, so I believe that inadvertent application on landing is almost impossible. The brakes have good proportional feel, an impressively low pedal pressure is needed, and will almost hold full power, yet with no perceivable tendency to lift the tail when stopping from a fast taxi.

One can lock a wheel and by pushing the stick forward of neutral, rotate about that wheel. This is on grass with the skid still fitted, like a tail dragger with a castoring tail wheel.

Iíve just reminded myself of the old adage "When I said I did my PPL on grass, I was referring to the runway surface."

Almost as importantly, the systemís aesthetic appearance is in keeping with the aircraft, indeed enhancing the authentic theme of the aircraft.

Ok, some of the 1920ís spirit and skills of operating and manoeuvring about without brakes have now been lost from my aeroplane but is a hell of a lot safer and less stressful!

We will be producing to order. The first production model of the brake system has been ordered for ĎYZ then we will be able to offer a definitive price for a set /kit. Drawings may be made available but we would recommend a set of our own manufacture as we have all the necessary tooling and know how, quicker, cheaper and problem free in the long run. Yes, Lynnís wheel makers built the wheels around our hubs with drums.

Rupert |

|

|

|

September 6, 2006 Group, Following the success of the brakes of G-ERIW, I've had several enquiries as

to weather the brake system is going to be made available to other builders. The answer it YES, both as complete systems and individual components. What

I don't have at the moment are any costs, but I'm in the process of making a

set for G-BYYZ and I'm carefully recording manufacturing times and the cost

of materials, so once completed I will be in a position to quote firm

prices. What I do have available is sets of bound drawings of the complete brake

system, consisting of over 60 drawings and component lists. They are available at £40.00 including postage in the U.K. and at £45.00

including postage in the rest of the known world. Jim Cresswell has just

received his set and I know is delighted with the detail and information

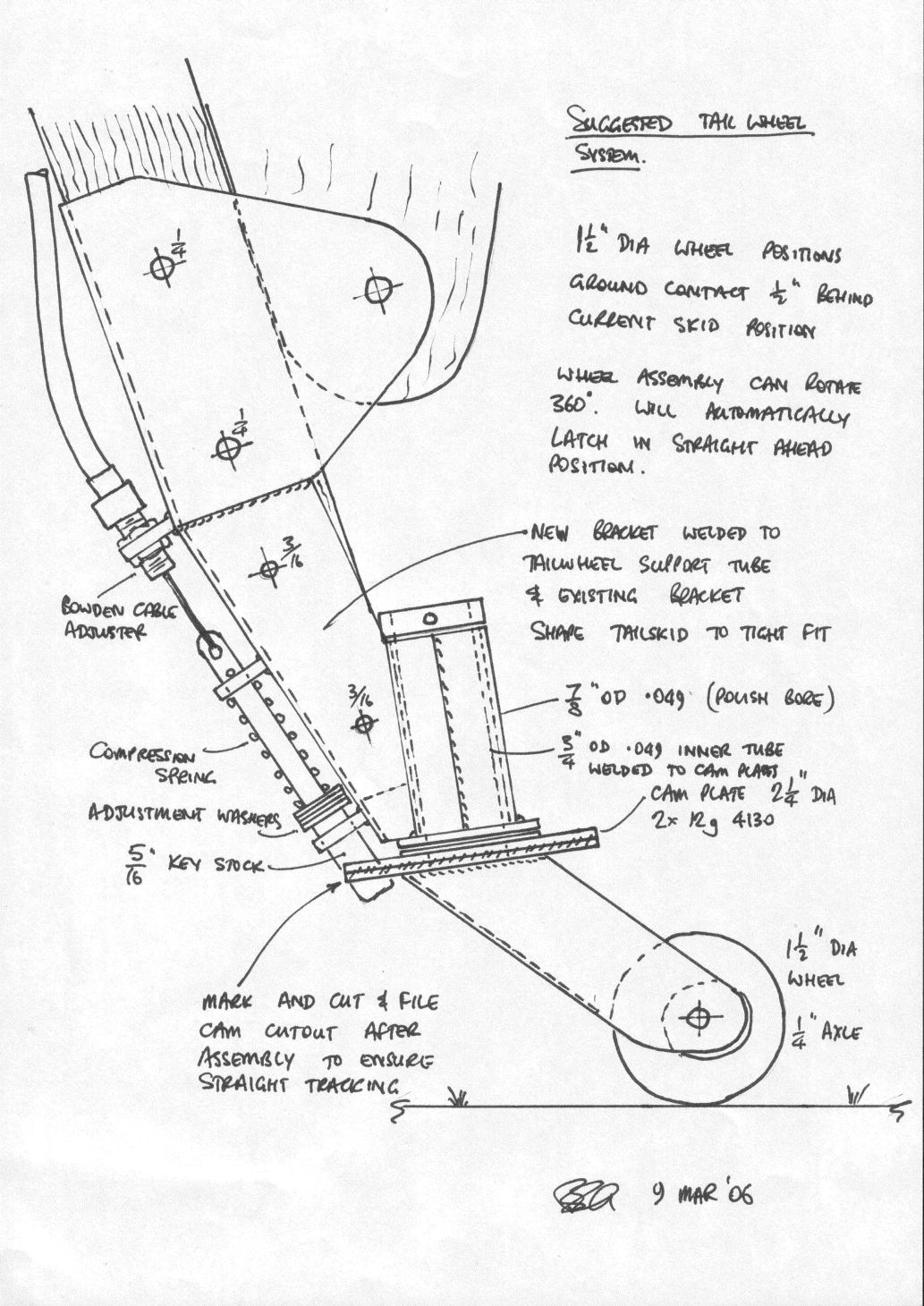

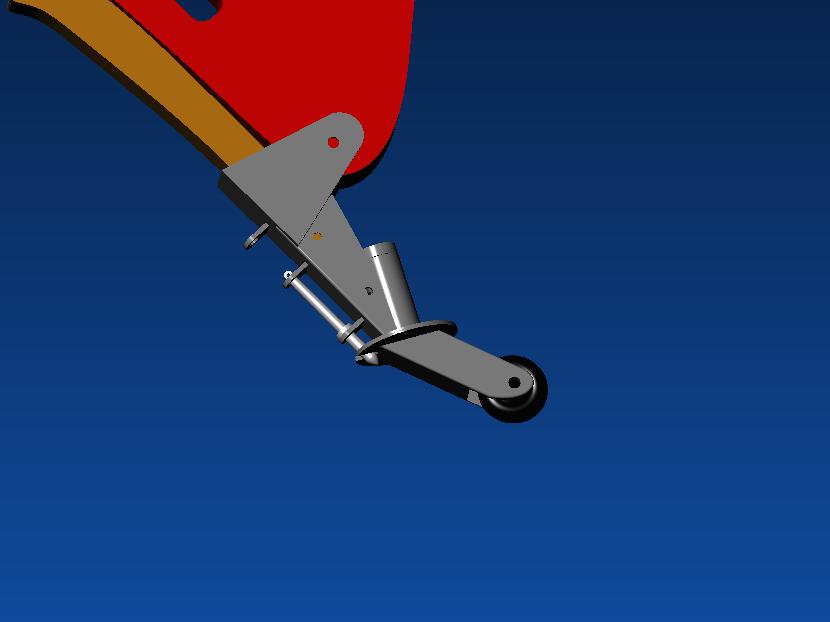

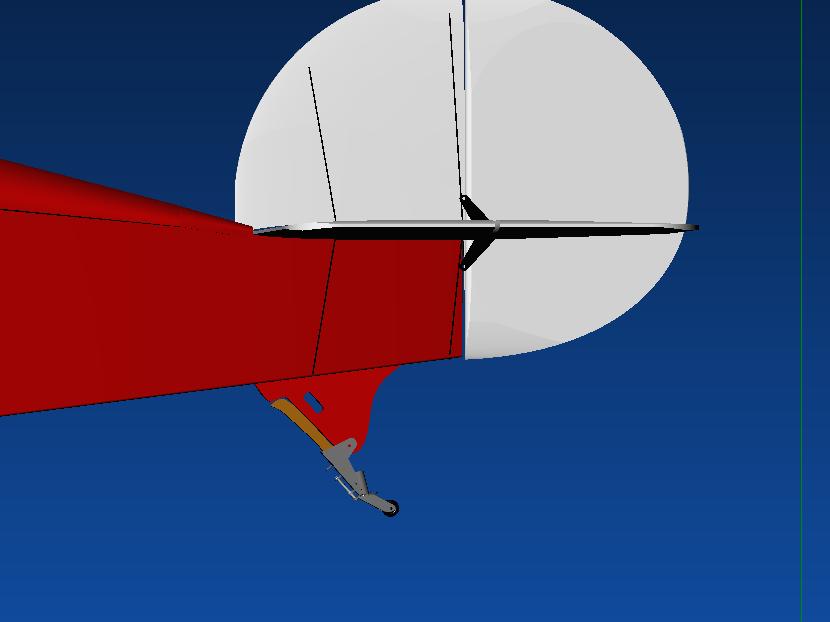

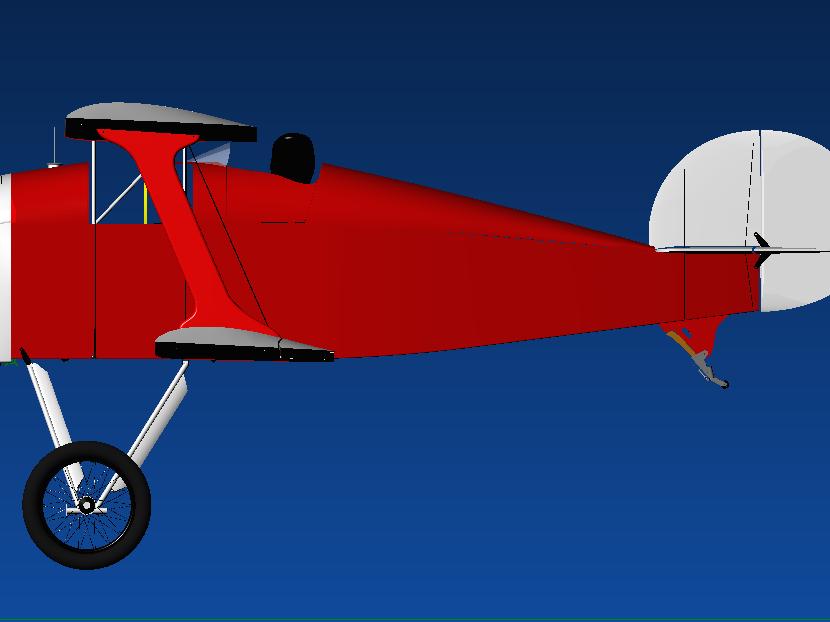

contained in them. Regards, September 8, 2006 Group, Here's a useful close-up of the brake design by Ian Wasey as fitted to G-ERIW. Photo courtesy of Chris Jefferson (who may be about to build a Meteor!). February 6, 2008 August 7, 2006 Certainly on grass, a tail wheel is not necessary. I am going to experiment with a skateboard wheel (diameter 44 x width 24) fixed, not castoring or steering, for hard surfaces, maybe even removable so it attaches by a very simple yoke bracket and a couple of pins, extending past the existing skid shoe to hold the skid just off the ground when operating on hard. If it is successful I will probably make it a permanent fixture, see attached drawing. My feeling is that a fixed wheel will work fine, especially if hard surface operation is only occasional. How much the wheel will suffer from scrubbing whilst being turned on concrete, I donít know. I think that a castoring tail wheel will be trouble in a cross wind when taxing and one could have sudden inadvertent weather-cocking swings with an uncontrolled castoring wheel on such a light aeroplane. Although mine will rotate about the axis of one wheel on grass with a skid, one doesnít really need to do that with a Flitzer as it is so light to lift the tail and park after shut down. So no, I donít think a castoring wheel is necessary but we will know the definitive answer when I get mine to Kemble. Here is another tailwheel system, with some ideas adapted from a design that Chris posted a while back, for the Boredom Fighter. While this design seems a little more complicated, it is really quite simple, and retains many desirable features: The new steel pieces are simple U shapes, with the upper piece then formed to meet the support tube, which is welded to it. The tailwheel fork, with the closed front side, will also act as a skid over rough ground. I'll let the idea gestate for a time before trying to make up this system. Comments and suggestions welcome. ...here is some rough CAD. One concern I have is the vulnerabilty of the locking pin, etc. to damage. Might we consider moving it to the rear of the assembly, cable routing issues aside...? It might then be possible to reduce the size of the locking disc. VS, I'd leave it exactly as it is. All it needs is a a 20 SWG aluminium shroud to keep out the dirt and mud, curving around the front of the lower assembly to cover the pin and spring, starting at the Bowden cable attachm't lug, which will also streamline the unit somewhat, below the bungee wrap. It will look extremely neat. Nicely drawn. Cheers,

mob 07885 257134

P.S. Off to put some more polish on my trophy!

See Rupert and Ian Wasey's new Flitzer web site!

www.waseyaeroplanes.com

Wasey brake and metal fitting kits for the Flitzer now available!

Rupert's Tailwheel Design

Brian Anderson's Tailwheel Design

- the wheel touches the ground 1/2 behind where the tailskid currently touches, and the ground angle of the plane is exactly the same.

- when unlocked the tailwheel assembly is free castoring over 360 deg, it is self centering when the plane moves forward, and will latch into the straight position if the bowden cable is released from the cockpit.

- the design incorporates what seem to be the most desirable angles for castor and offset.

- with only a very minor modification the system will accommodate wheel diameters up to 3".

- the tube pivot system [shimmed with brass] can incorporate an oil dam and some lubrication holes to be self oiling.