Flitzer Sport Flying Association

Dudley Pattison's Flitzer Stummelflitzer Z-1R

August 22, 2007

Hi all,

Just thought I would share my first efforts at engine turning with you. I was a virgin as far as this art was concerned and had no idea how long it could take. Just short of forever. But it is a strangely satisfying task.

Duds

|

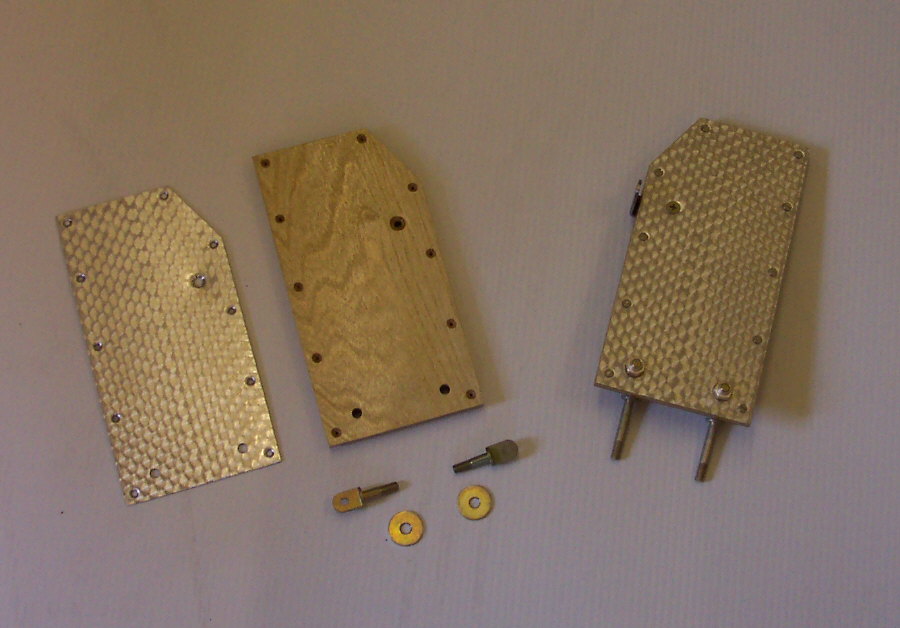

Photo 1 shows my rudder pedal 'kit'. The pedals were made by laminating 3mm ply to each side of 6mm ply that had lightening holes in strategic positions. I did it this way simply because I didn't have any suitable 12mm ply. |

|

|

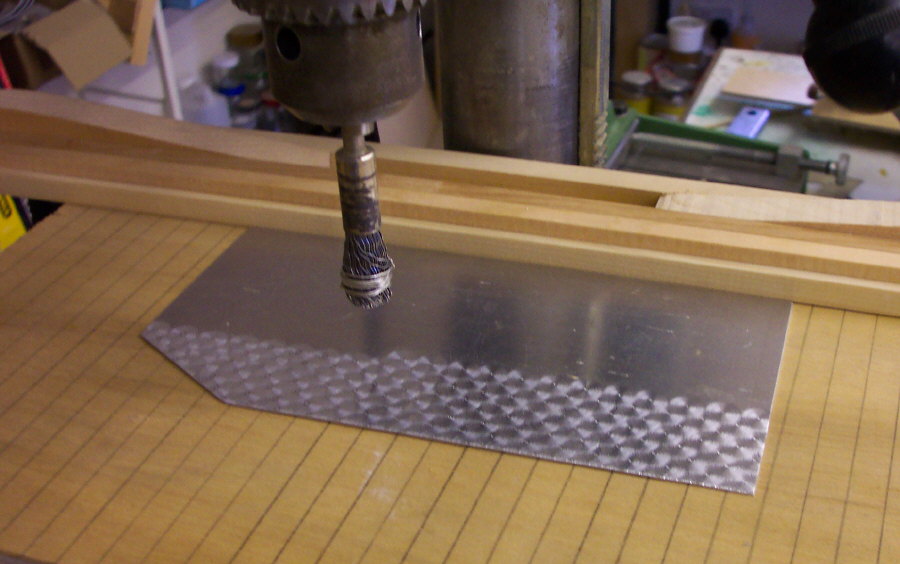

Photo 2 shows an aluminium faceplate being engine turned on the pillar drill. My first mistake was to use an old 1/2" diameter bullnosed wire brush. The last time I used it was to clean up the s/h 0235 for the Fury in '89. I ground it flat on the end after binding as shown on Lynns drawing. I think I would have got a more consistent from a new one. (I know, bad workman and tools etc). |

|

|

Photo 3 shows a completed pedal and one in component parts. No 4 x 3/8" stainless screws are used to attach the plate to the ply (I have a natural aversion to Evo Stik and similar impact adhesives). The 3/4" washers (which sit under the heads of the eyebolts) were standard penny washers for 3/16" bolts and so had to be drilled out for the 1/4" eyebolt 'hinges'. T'is worth noting that the eyebolts, being properly made, have a small radius under the head so the washer hole needs to be lightly countersunk to accomodate this and allow proper tightening of the nut. |

|

November 8, 2007

Group,

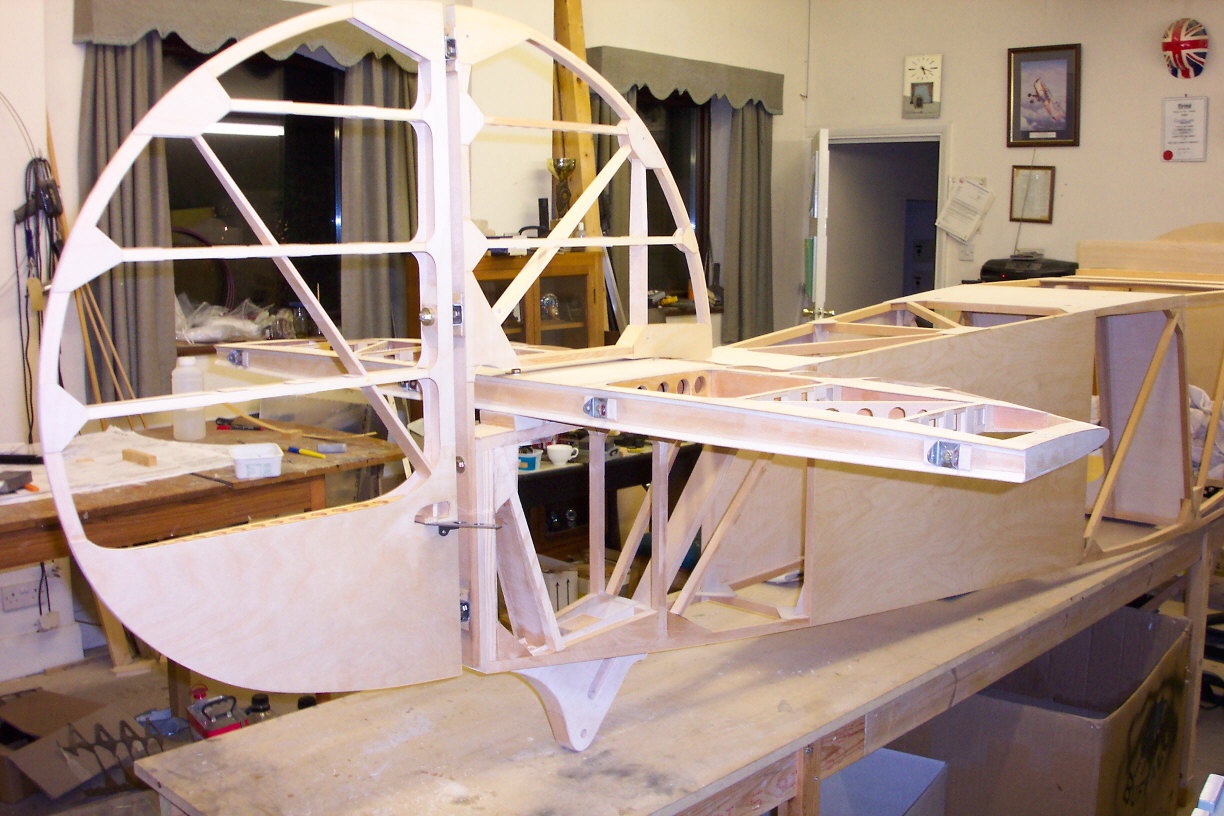

Pictures of Dudley's Type R tailgroup. Super workmanship is the order of the day for Flitzers.

He reckons that the fin and rudder look small, but they're about the same size as those of a Sopwith Camel and I recall that was extremely manoeuvrable. The four ailerons of the Types S & R will make the CGI roll-rates of the Albatros D.Vs in The Red Baron look tame! :0)

Lynn