|

|

|||||

| 2 | 3 | 4 | 5 | |||

| 1 | 1.2MB |

| 2 | 672KB |

| 3 | 865KB |

| 4 | 1.0MB |

February 23, 2008 - SuperGoblin Progress

Hi,

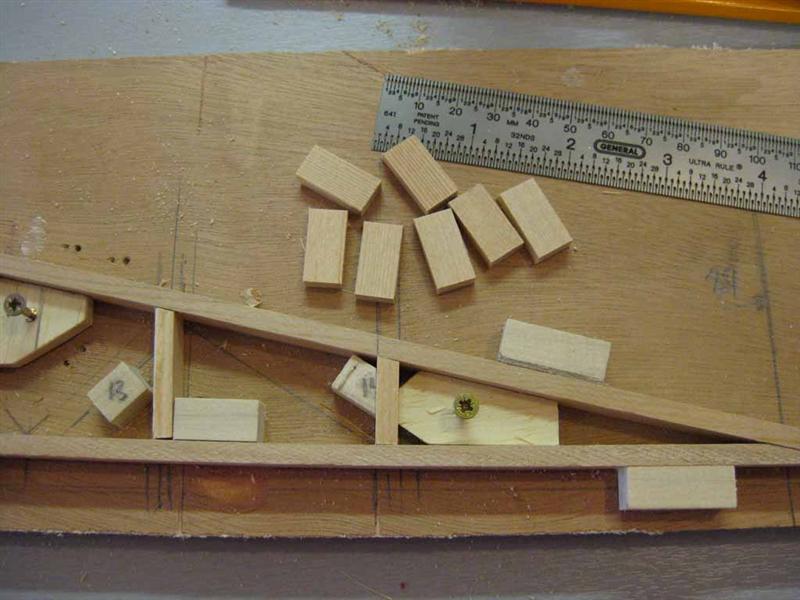

Here are a few images of the SuperGoblin progress. I have recently cut and fitted all corner blocks. Speaking of them Lynn are they big or small enough? For curiosity the corner blocks weighs 600 grams total. Nothing is glued yet since it it is still below zero Celsius here and an unheated workshop.

Robert

May 14, 2008 - Die Flitzer Zeitung

Hi,

Inspired by the great inventor of the newsletter, Baron von Morrisov, the souther boy, Gottfried Himmelsschreiber, made his first newspaper "Die Flitzer Zeitung" in 1928. He used only an electrifying Type-O-Writer connected with a simple ink-press, the so called Dell-Ani Kanonov technique, to make his new creation. Die Flitzer Zeitung was an instant success! Thanks to the generous sponsors Flitzer Brau and Flitzer Designs the price could be kept low.

I manage to find this rare copy of "Die Flitzer Zeitung", Elevation 1 and I am now going to sell it off at an auction, I will probably get at least 2 cents for this priceless antique dating back to 1928.

The scanned newspaper can be found here

Dead serious! I don't think so........have fun!

Robert

- In the next Elevation: I will tell the readers how the auction went! -

May 22, 2008 - How to cut your cut time by 4

Hi,

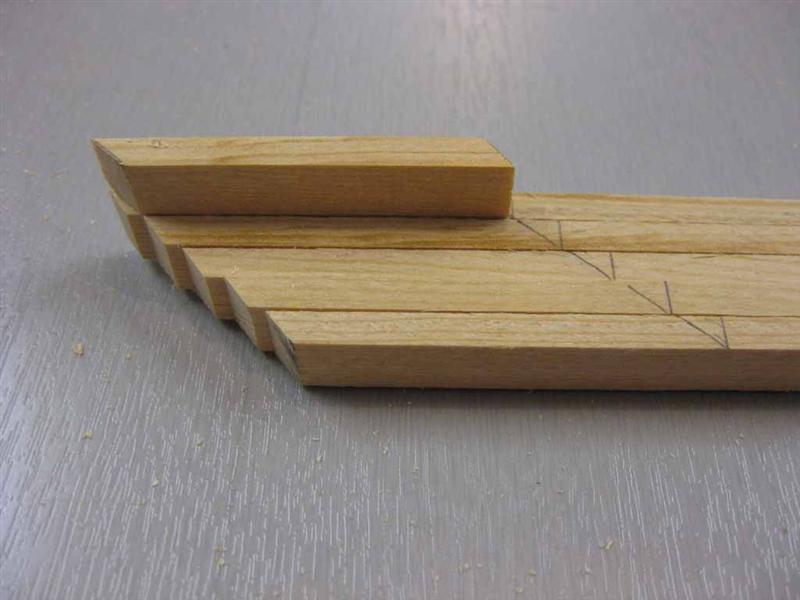

I manage to cut the cut time by 4 by using my SSMS-Ninja. (Swedish Samurai's Miter Saw - Ninja)

Cutting 2 angled pieces are little bit tricky, but possible. It require some practice first...schwoooch....schwoooch......HAI !

Use the master piece and turn it around and line up the pieces as shown in the picture (#6). Hold pieces together with clamp, cut at the correct location (1 cut).

Just the wing ribs are about 500 cuts so this would cut it down to about 125 cuts!

The Ninja Troll

|

|

|

|

|

|

Thanks for the tips there, von Troll.

Note: from the size of the cross-sections in the confined space near the trailing edge of the Goblin aileron ribs, the optional diagonal addition(s) is probably an unnecessary refinement, given that there will be vertical 1.0 mm plywood gussets centered on the uprights.

It might be worthwhile to make a scrap aileron rib and load it at the TE with the 'spar' end fixed and see what weight it will bear!

Lynn

Hi Lynn,

Here is a better image of the aileron rib with the diagonal in place.

I will do two scrap ailerons (with and without the diagonal) and test them.

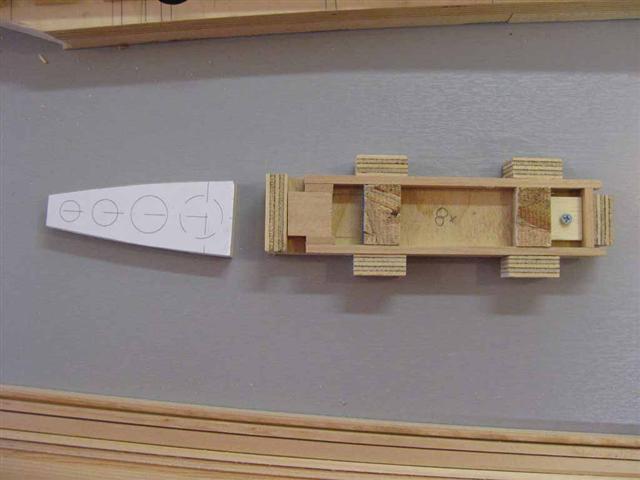

Here is also the tail rib jig and tail nose form (to be used with a router).

Robert

|

|

May 26, 2008 - Tailplane and elevator comparison

Hi Lynn,

I worked on an elevator rib jig for the Goblin and have a question about small uprights on the elevator and tail plane on the Goblin. On the Z-21 tail plane there is a similar set up but with uprights. See my image. What are your thoughts about not using the uprights on the Goblin? I might understand that the tail plane would have less force on it but the elevator would see some force in that direction, right? I just had some concern that the plywood would bow under pressure.

Any comments?

Robert

Hi Robert,

The stiffness of the ply webs, given the grip involved, will prevent bowing on the shorter chord tailplane and elevator of the Z-1K. I have by the way built the Goblin rudder ribs (which are relatively deep sections) and these are impossible to deform more than a millimetre with hand pressure with no spruce cross-members.

Generally, though light, most Flitzers are slightly over-built, for durability. The tailplane on the Z-1K is of course entirely ply-skinned which adds considerably to the stiffness. Compared for example to the fully cantilever tailplane of something like the Brugger Colibri, the strut-braced tailplane is stronger and even has a forward spar, unlike the Brugger, which relies entirely on the rear spar and its leading edge for lateral stiffness with no more support in the rib structure than there is on the Goblin - and no strut.

By all means add an upright if you wish. Again, it might be worth building a scrap rib without the upright and squeezing it. My concern with the Goblin was to keep the tail-end extremely light, hence the holes drilled in the plywood gussets. Incidentally, the 14 SWG tailplane strut bracket on the sternpost is overkill and can easily be replaced by 16 SWG for 2/3 of the weight.

Best wishes,

Lynn

Thanks Lynn,

for a fast response, as always.

I just had some thoughts about it since the ailerons are only about 10" from hinge to trailing edge and the elevator is about 14.75 inches from hinge to trailing edge. The ailerons have extra uprights but not the elevator.

Here are the jigs for the tail plane and elevator, all put in close formation. It totals 28 inches (with the added 1 inch on the nose rib and 1.5 on the elevator) from tip to trailing edge (even though the ruler does not show so due to it is lower than the jigs). Trailing edge and spars are not shown clearly. The black plastic tube indicates the hinge location. Plywood pieces not shown either.

Robert

June 15, 2008 - Bend jig and tools

Hi,

Here is 2 bend and glue jigs for the Goblin. In the picture the wood is being bent. The blue clamps in the pictures are currently on sale at Harbour Freight for $1.99 each, good deal if you need many or as von Schmirk puts it " you need all of them!".

I made a circle cutter for my router (the one without antenna), to the left of the bend jigs.

I am currently working on a drill press table, not yet finished. When finished it will be possible to put a router underneath as well. Just not use both at the same time!

Robert

|

|

Hi Robert,

It looks as if you have really decided to make up for lost time now! Are those two curves for the rudder LE and TE upper laminations?

Good work von Troll!

Lynn

Hi,

The larger radius is for the tailplane and elevator and the smaller for the LE of the wing panels. That may work for the rudder LE as well, I think.

Robert

|

|

|||||

| 2 | 3 | 4 | 5 | |||