|

2 | 3 |  |

|

| Lo-Res | Hi-Res | |

| 2011 - March | 3.0MB | |

| 2010 - June | 2.4MB | |

| 2008 - December | 1.2MB | |

| 2008 - April | 496KB | |

| 2007 - October | 500KB | 2.9MB |

| 2007 - March | 781KB | 2.7MB |

| 2006 - August | 804KB | 2.3MB |

| 2006 - May | 652KB | 5.5MB |

| 2006 - March | 320KB | 5.4MB |

| 2006 - January | 157KB | 1.84MB |

| 2005 - October | 274KB | 2.4MB |

June 23, 2005

Hi Blake -

Work is progressing well on my Flitzer. So I was wondering - can you include me now under Flitzer builders on the web page?

The attached zip file has a photo of the fin and rudder, and the proposed color scheme for my Flitzer.

John Morris

|

|

August 7, 2005

Hi Blake -

Latest progress report for the website (jpg attached) - A major milestone for the Connecticut Flitzer Werke - the tail is now structurally complete, and the balsa nose on the elevator will await the completion of the hinges. On to the wings! The plywood skinning of the stabilizer and elevator took rather longer than I expected partly due to the 18 scarfed joints (that's 36 scarfed surfaces).

cheers - Baron Ivan Morrisov

August 25, 2005

Dear Baldamus

Does the attached photo answer your question on finishing the rib noses? I made a jig to place each one in after the rib was made and fed it into the table router nice and straight to cut the groove without any wobble or chatter. This setup will of course require a full-wraparound plywood leading edge - another challenge in bending wood to one's will (if one is lucky!!)

I used the same router jig for the in-between nose ribs so all the grooves are exactly the same - helps keep that leading edge straight! Different jigs, of course, for upper and lower. The noses will get a coat of sealant (though not on the gluing surfaces) before sealing them up in that D-section.

cheers - The Baron

Connecticut Flitzer Werke

August 25, 2005

...I am finding it such fun that I am building two spare ribs while I am at it. One will be a Christmas present for a friend, the other I will hang on my office wall. Works of art, each and every one of them evoking the skills, challenges and romance of the past and chanelling them into life today...

It's a bit early in the morning for philosophy so I shall get back to the Flitzer Werke!

cheers - The Baron

Connecticut Flitzer Werke

September 1, 2005

Progress!!!

Components for NX969 continue to mulitply. Now awaiting spruce spars, but I am off to Canada, then China and Germany for work; the hiatus fits perfectly, new supplies should be waiting when I get back. Shipping charges for the spars proved to be quite high, so I added an order for the fuselage longerons to maximize use of the crate! With Gary's metal kit on order I am looking to wing assembly for the remainder of this year.

Our household garlic and apple press is on order. Every family should have a 20 ton hydraulic press to perform these vital tasks, and when not so employed it can be used to bend metal fittings accurately without stressing them...Photos when it becomes operational.

Highlights of August were the meeting of the FSV and Flitzerbrau with Chris Bobka at the Connecticut Flitzer Werke, aviation photographer (and author of the book on Old Rhinebeck) Mike Vines making a wing rib and signing it off with a ceremony in true air show tradition, and my first look at drawings for the Goblin.

Prost!

The Baron

Connecticut Flitzer Werke

October 28, 2005

Hi Gang -

So many of my friends are asking about progress on the Connecticut Flitzer, indeed, what is a Flitzer, that I decided to produce an infrequent newsletter for them on the latest activities of the Connecticut Flitzer Werke. Attached is Issue No. 1 - pdf file.

If anybody would like a high resolution version (2.3 mb) please email me offline.

Prost!

Baron Ivan Morrisov

January 3, 2006

The Connecticut Flitzer Werke has been busy on the Morrisov machine.

Latest progress is detailed in the attached newsletter.

Prost!

The Baron

March 6, 2006

Hi Group -

Wings were the theme on three continents this weekend, as Mark and Vic attached theirs for the first time and The Baron finished the first one in the Americas.

Attached is the latest newsletter from the Connecticut Flitzer Werke (pdf file, low res).

Prost!

The Baron

March 23, 2006

Group,

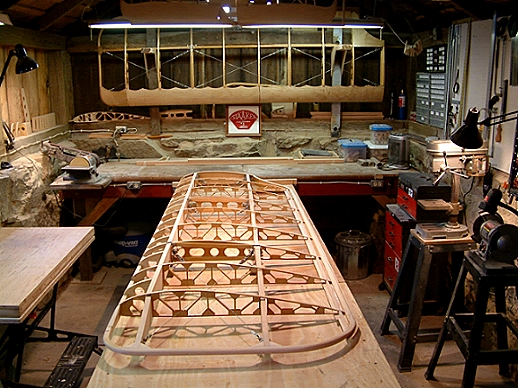

Herewith the latest pictures from Ivan Morrisov, who hopes to have the two remaining wings done by the middle of the year. The workmanship is exemplary and can be clearly appreciated on the original size pictures.

Note the concave shape of the rear spar tip, upper-edge to clear the fabric-line to the wing tip, as recommended on the drgs.

Excellent work , Ivan.

Tschuss,

K. [Lynn]

|

|

May 20, 2006

Hi Group -

Finishing the second wing has triggered a new newsletter. Also featured - Morrisov's nostalgic visit to Staaken airfield, and the first recognition of the Flitzer in an Aviation Week publication, at the Berlin air show.

Prost! - The Baron

July 31, 2006

On July 30 I finished building Wing 3 (structurally), and started Wing 4. At last! Life as it should be!

Attached are a few pics.

|

|

September 10, 2006

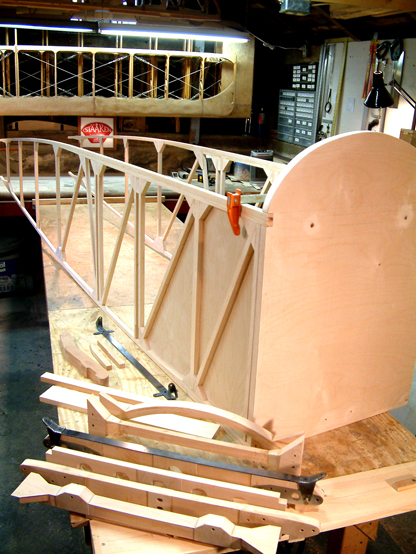

Celebrations here at the Connecticut Flitzer Werke with the structural completion of the fourth wing, and beginning of the first fuselage parts.

Prost! - Morrisov

Connecticut Flitzer Werke

All the Morrisov newsletters are available at the top of this page. - Blake

September 23, 2006

All the major forward fuselage parts and carrythroughs have now been made (photo attached).

Having built the firewall frame I realized that the very same jig determined the exact dimensions of the width of the fuselage. Therefore it could also be used as the jig to make all the cross beams and carry throughs. Two tricks - use the very same longeron wood in the jig as will be used in the fuselage, as not all 5/8th inch wood is trimmed to the same 5/8ths. And use 1mm or 1.5 mm plywood to pack the sides in the jig to represent the inside skinning of the fuselage sides.

The jig used to laminate the arch on top of the firewall was also used to laminate the other three forward fuselage arches, with an allowance for longer vertical sides. This way the curve is the same on all four arches.

Progress!

Prost! - Morrisov

Kameraden -

The latest milestone at the Connecticut Flitzer Werke is the first trial fit of the firewall with the two fuselage sides - photo attached (low res).

Other highlights include taxiing Ernst Kessler's original Flitzer in Wales early in November, picking up a set of wheels with Ian Wasey's superb brake drum hubs, and the imminent arrival of my brother in Connecticut with the rest of Ian's fabulous brake kit.

Progress every day!

Prost!! - Morrisov

Connecticut Flitzer Werke

|

2 | 3 |  |

|